|

|

|

|

|

|

|

|

FDI-DICHTUNGEN®

|

|

| FDI® - shaft seal |

|

model: F2 + F8

|

|

|

|

|

|

|

|

|

|

|

- for single and multiple application

|

with grooves for lubrication: |

|

|

|

Example for application:

|

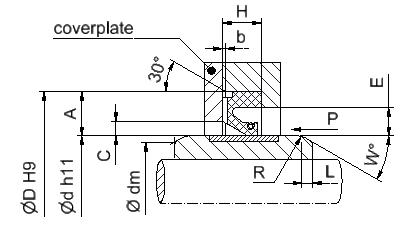

figure 1

|

|

|

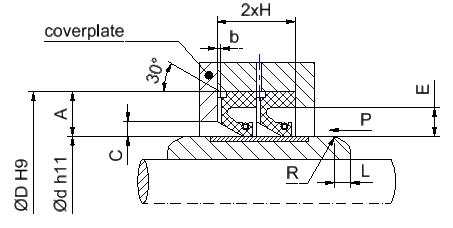

figure 2

|

|

|

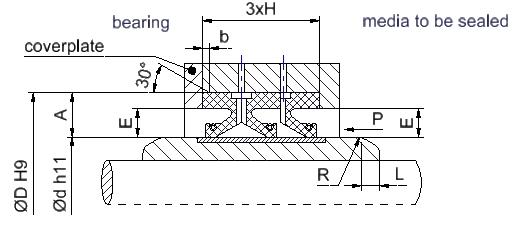

figure 3

|

|

|

P = pressure side

|

|

|

housing dimension:

| H (mm) |

H |

2 x H |

3 x H |

|

tolerance |

| to 19 |

±0,1 |

±0,1 |

±0,1 |

| up 20 |

±0,2 |

±0,2 |

±0,2 |

|

|

|

|

| C (mm) |

E (mm) |

b (mm) |

| A x 0,2 |

A x 0,5 |

H x 0,12 |

|

|

|

|

|

| lubrication: |

requested! (above approx. ca. 0,2m/s ) |

| media to be sealed: |

foods stuff, oil, grease, water, suspension with hard particles. |

|

|

| model |

radial runout

|

operating pressure max.

|

|

|

mm / max.

|

Bar

|

MPa

|

| F2 |

endless |

1,5

|

1

|

0,1

|

| F8 |

split |

1,5

|

low grade

|

|

|

Ø range of

d (mm) |

cross section *

A=D-d H

2 |

radal runout

mm max. |

axial movement

mm unlimited |

| <50 |

11 10 |

0,6 |

∞ |

| >50 - 100 |

16 12,5 |

0,75 |

∞ |

| >100 - 250 |

20 16 |

0,9 |

∞ |

| >250 - 400 |

22 20 |

1,0 |

∞ |

| >400 - 600 |

25 22 |

1,2 |

∞ |

| >600 |

32 25 |

1,5 |

∞ |

|

|

further profiles on request.

The indicated data are limits and can´t be combined!

|

|

|

material:

|

temperature

°C

min. max.

|

speed

m/s max.

|

chemical

resistance

|

| FDI® 1002 |

-40 +120 |

15 |

as NBR |

| FDI® 2002 |

-40 +170 |

25 |

as HNBR |

| FDI® 3002 |

-30 +200 |

30 |

as FKM (FPM) |

|

|

|

|

Lead in chamfer

|

(length of lead chamfer mm)

|

| W=30° |

W=25° |

W=20° |

W=15° |

|

|

Ø d (shaft Ø mm)

|

Ø dm max

|

L

|

L

|

L

|

L

|

R

|

|

up 30 - 40

|

d -3,0

|

2,6 |

3,2 |

4,1 |

5,6 |

3,0 |

|

up 40 - 50

|

d -3,5

|

3,0 |

3,7 |

4,8 |

6,5 |

3,5 |

|

up 50 - 70

|

d -4,0

|

3,5 |

4,3 |

5,5 |

7,5 |

3,5 |

|

up 70 - 95

|

d -4,5

|

4,0 |

4,8 |

6,2 |

8,4 |

4,0 |

|

up 95 - 130

|

d -5,5

|

4,8 |

5,9 |

7,6 |

10,3 |

5,0 |

|

up 130 - 240

|

d -7,0

|

6,0 |

7,5 |

9,6 |

13 |

6,0 |

|

up 240 - 400

|

d -11,0

|

9,5 |

11,8 |

15,1 |

20,5 |

10 |

|

> 400

|

d -12,5

|

10,8 |

13,4 |

17,2 |

23,3 |

10 |

|

|

size list*

| d |

D |

H |

A |

CAD

Download

|

| (mm) |

(mm) |

(mm) |

(mm) |

|

| 090 |

115 |

11 |

12,5 |

|

| 130 |

170 |

16 |

20 |

|

| 150 |

180 |

12 |

15 |

|

| 160 |

200 |

16 |

20 |

|

| 200 |

230 |

15 |

15 |

|

| 200 |

240 |

16 |

20 |

|

| 220 |

250 |

15 |

15 |

|

| 220 |

260 |

16 |

20 |

|

| 225 |

265 |

16 |

20 |

|

| 230 |

260 |

15 |

15 |

|

| 255 |

299 |

20 |

22 |

|

| 260 |

300 |

16 |

20 |

|

| 284 |

328 |

16 |

22 |

|

| 300 |

340 |

16 |

20 |

|

| 300 |

344 |

20 |

22 |

|

| 355 |

399 |

20 |

22 |

|

| 380 |

424 |

20 |

22 |

|

| 400 |

444 |

20 |

22 |

|

| 425 |

475 |

20 |

25 |

|

| 430 |

480 |

22 |

25 |

|

| 455 |

505 |

22 |

25 |

|

| 525 |

575 |

22 |

25 |

|

| 530 |

580 |

22 |

25 |

|

| * other sizes on request |

|

|

|

|

|

The data shown above is based on long lasting experience in the manufacturing and use of sealing

elements. As there are many unknown possible parameters and conditions in practice, which may

limit standard performance, it is requested that the user runs practical tests. Except as expressly

stated, Friedrich´s liability, expressed or implied, is limited to the published selling price of our

defective item.

© Issued under copyright and must not be used for any purpose without written permission from the copyright owner.

|

|

|

FDI® and FDI-DICHTUNGEN® are registered trademarks of Friedrich GmbH

|

|

|

|

|

© 2016/1 by FDI® - Design

|

|

|

|

|

FDI-025-F2+F8_e

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|